+86 15633683072

Automobile Body Production Line Welding Fixtures

Automobile Body Production Line Welding Fixtures  Automotive Body Welding Automated Manufacturing Solutions

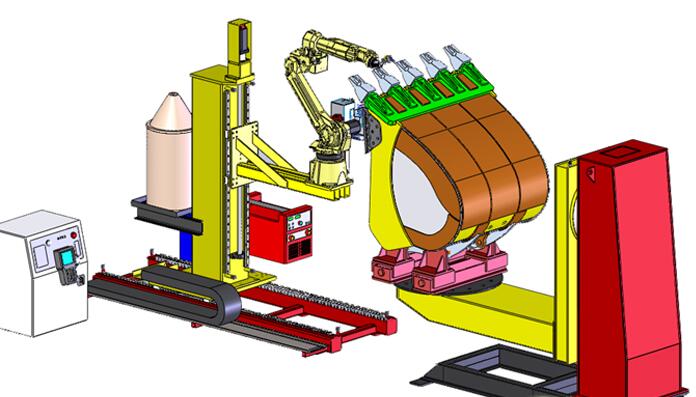

Automotive Body Welding Automated Manufacturing Solutions  Bulldozer beam and bucket robot welding cobot assembly line

Bulldozer beam and bucket robot welding cobot assembly line  Suspension parts of semi-trailer fully automated production line

Suspension parts of semi-trailer fully automated production line  Aluminum alloy container side box robot automated welding manufacturing line automation

Aluminum alloy container side box robot automated welding manufacturing line automation Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com